Introduction

Chemical safety data sheets (SDS) serve as essential tools for ensuring workplace safety in environments where hazardous substances are present. By mastering the intricacies of SDS, organizations can enhance their compliance with OSHA standards and protect employee well-being. Despite this, millions of workplace injuries are reported annually, highlighting a critical challenge:

- How can organizations effectively access, understand, and utilize these vital resources to mitigate risks and cultivate a culture of safety?

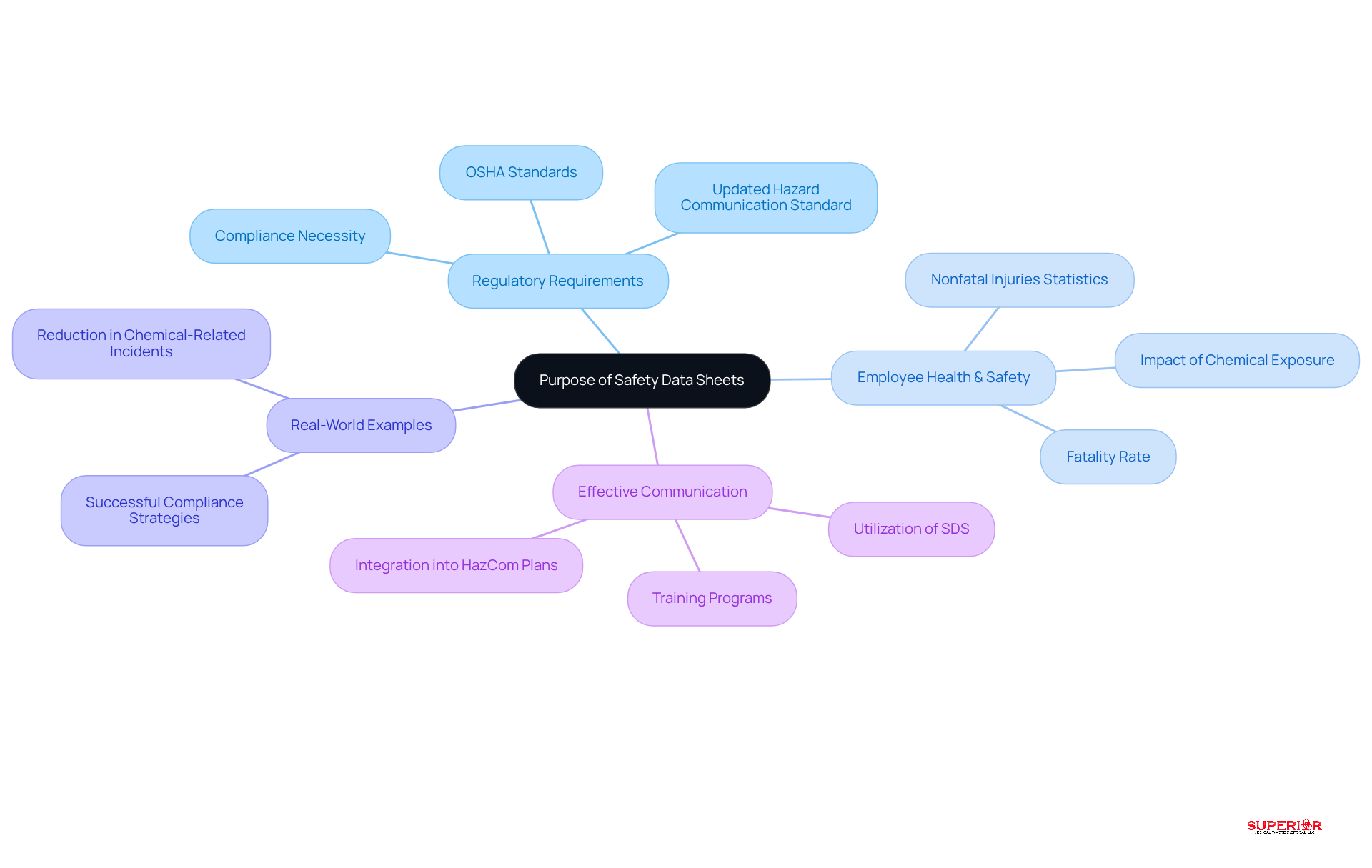

Understand the Purpose of Safety Data Sheets

Chemical safety data sheets online are essential documents that provide comprehensive information about hazardous substances, detailing their associated risks, safe handling procedures, and emergency protocols. These sheets, known as chemical safety data sheets online, are not just informative; they are a regulatory requirement under OSHA standards, which mandate that employers ensure access to them for all hazardous materials in the workplace. Compliance with these regulations is crucial, as it directly impacts employee health and safety.

In 2023, OSHA reported around 2.6 million nonfatal workplace injuries and illnesses, underscoring the urgent need for effective communication regarding hazardous substances. The updated Hazard Communication Standard, revised in 2025 to align with the Globally Harmonized System (GHS), highlights the necessity for accurate and accessible SDS. Employers must ensure that chemical safety data sheets online are not only available but also thoroughly understood by their staff to reduce risks associated with hazardous materials.

Real-world examples demonstrate the importance of SDS in compliance efforts. Organizations that have established robust systems for managing chemical safety data sheets online have reported significant reductions in chemical-related incidents. This proactive strategy not only cultivates a safer work environment but also aligns with OSHA’s commitment to decreasing workplace injuries and fatalities, which were recorded at a rate of 3.5 per 100,000 full-time equivalent workers in 2023, emphasizing the ongoing risks that SDS can help mitigate.

OSHA representatives emphasize that effective communication of chemical hazards through chemical safety data sheets online is vital for compliance and ensuring employee well-being. As stated, “Employers must ensure they receive updated SDS and shipped container labels from their suppliers, and then actually utilize the details to revise their written HazCom plan and training program.” This underscores the necessity of integrating chemical safety data sheets online into the broader framework of workplace protection and compliance strategies, ultimately safeguarding employees and enhancing operational efficiency.

Identify Key Components of Safety Data Sheets

Safety Data Sheets (SDS) are structured into 16 essential sections, standardized under the UN’s Globally Harmonized System (GHS). Each section delivers critical information about hazardous chemicals, making it imperative to understand them for workplace safety and regulatory compliance.

- Identification: This section includes the product name, manufacturer details, and emergency contact information, ensuring quick access to vital data during emergencies.

- Hazard Identification: It outlines potential dangers associated with the substance, including health risks and environmental impacts, which are crucial for effective risk assessment and management.

- Composition/Information on Ingredients: This section lists the chemical ingredients and their concentrations, aiding users in understanding the chemical’s makeup and any trade secret claims.

- First-Aid Measures: Instructions for responding to exposure or accidents are detailed here, enabling prompt and effective action in emergencies.

- Fire-Fighting Measures: This section specifies appropriate extinguishing methods and identifies hazards related to fire, which is essential for emergency preparedness.

Each section plays a significant role in hazard communication, with updated guidelines emphasizing the need for clarity and accessibility. For instance, the hazard identification section is vital for recognizing common risks, such as toxicity or flammability, which can significantly impact workplace security.

According to OSHA, chemical safety data sheets online must be readily available to all workers in their work area at all times, emphasizing the importance of accessibility for compliance and protection. Furthermore, facilities must adhere to SDS revision and resubmission requirements within 90 days of discovering new hazard information starting in 2025. Experts assert that well-organized SDSs not only facilitate adherence to OSHA regulations but also enhance the overall safety culture within healthcare facilities. Richard Flynt underscores the importance of training employees on how to access and understand SDSs, which is essential for effective substance management. By ensuring that all employees have access to and comprehend these key components, organizations can better manage safety regarding substances and respond effectively to potential incidents.

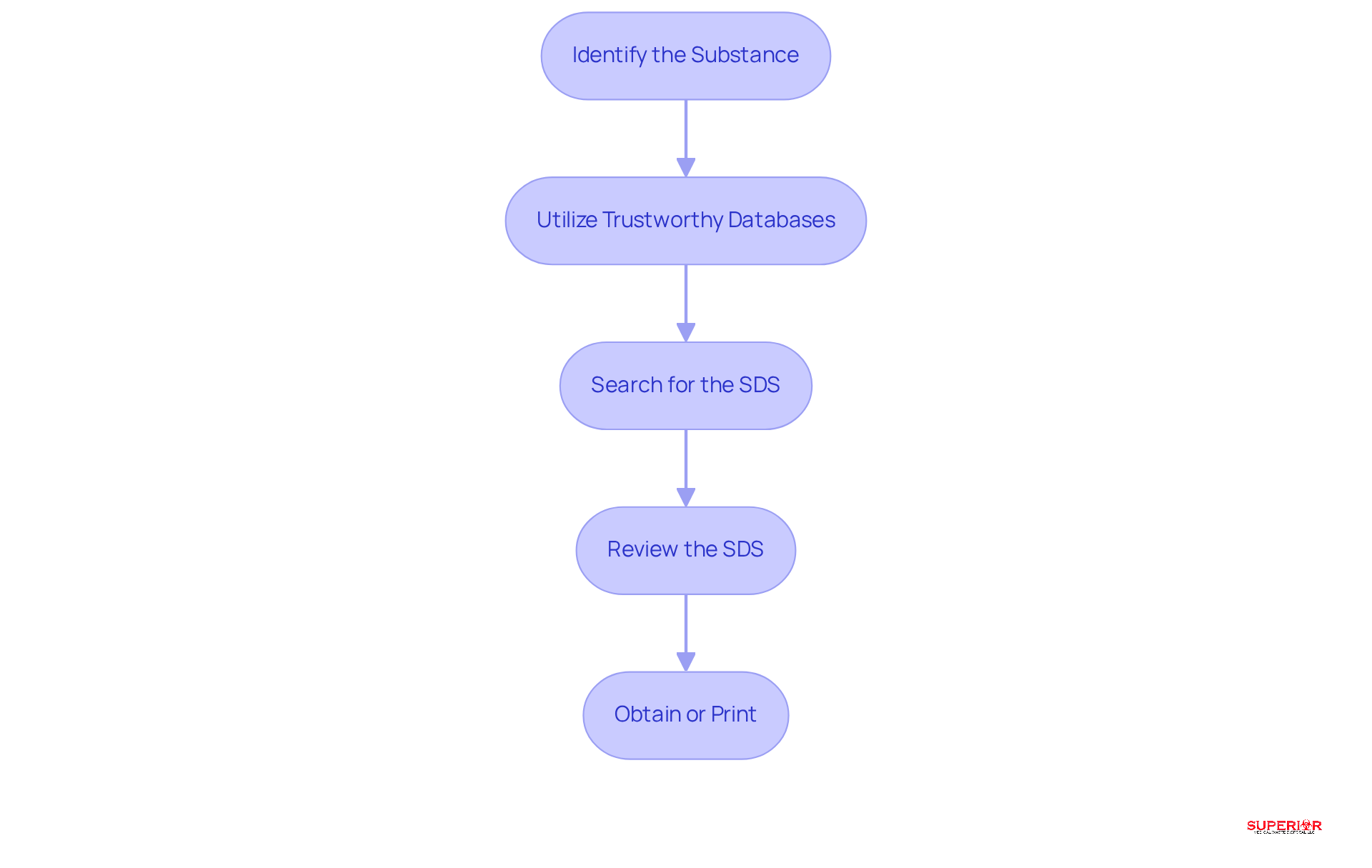

Access and Utilize Safety Data Sheets Online

To effectively access Safety Data Sheets (SDS) online, follow these best practices:

- Identify the Substance: Start by knowing the substance’s name or its CAS number. This knowledge will streamline your search process.

- Utilize trustworthy databases to access chemical safety data sheets online, including reputable sources like Safety Data or the specific website of your supplier. Many manufacturers provide SDS directly on their product pages, ensuring you receive the most accurate information.

- Search for the SDS: Enter the chemical name or CAS number into the search bar of the database. Selecting the correct product from the search results is crucial to avoid confusion.

- Review the SDS: Examine the SDS thoroughly to understand the related hazards and precautionary measures. This step is vital, as 34% of SDSs include unclear handling and storage details that may not sufficiently address hazard statements. Additionally, 56% of SDSs were found to be ‘not suitable’ for first-aid instructions, underscoring the importance of understanding these measures.

- Obtain or Print: For convenient access, obtain or print the SDS and keep it in your facility’s protection binder or digital library. This practice ensures that security details are easily accessible, which is essential for compliance and emergency readiness.

By adhering to these steps, you can maintain access to the most up-to-date and pertinent chemical safety data sheets online, which significantly enhances workplace security and compliance. Effective management of SDSs is vital for ensuring worker well-being and safeguarding organizations from audits. Furthermore, the Hazard Communication Standard (HCS) has aligned with the Globally Harmonized System (GHS) since 2012, emphasizing the importance of using updated SDSs.

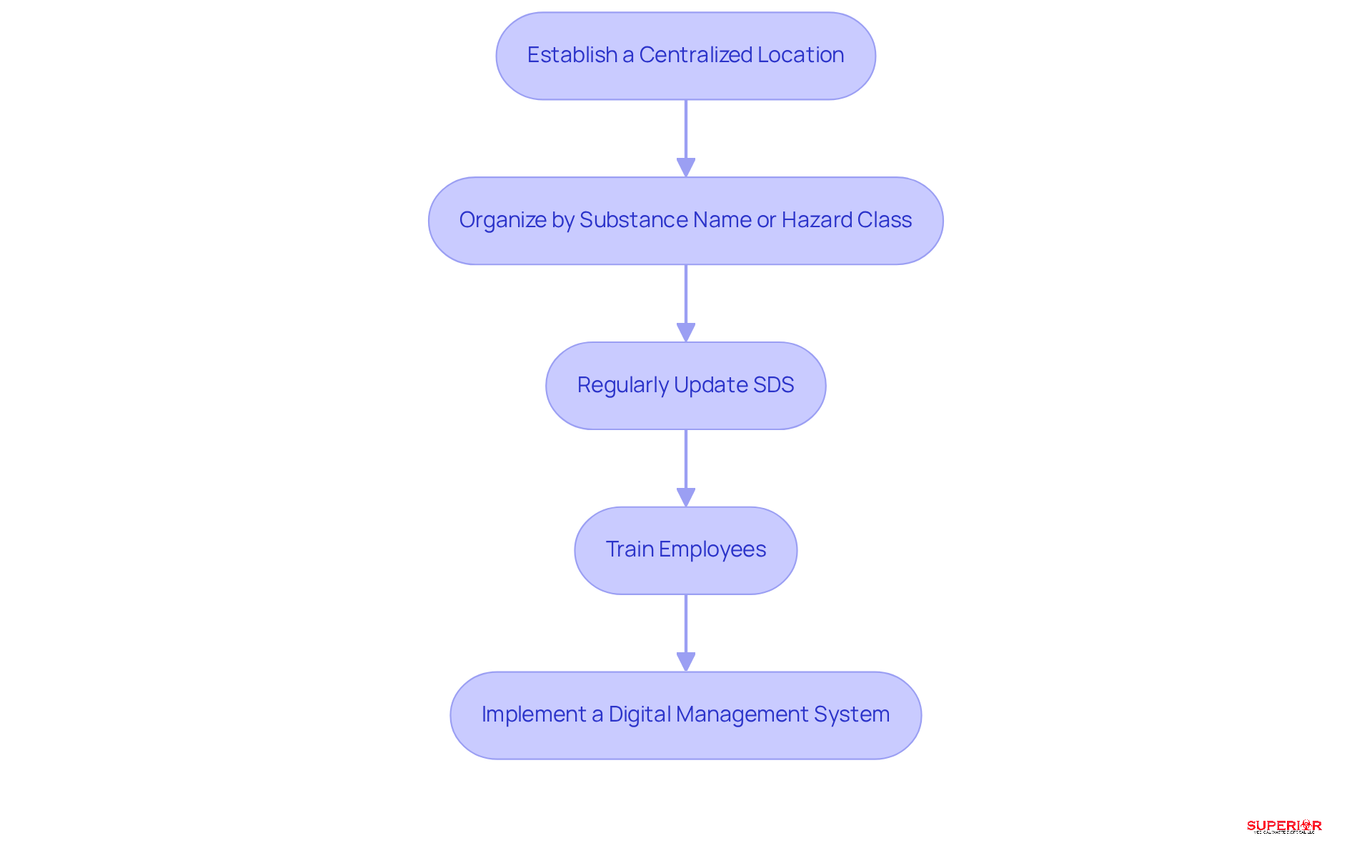

Maintain and Organize Safety Data Sheets in Your Facility

To effectively maintain and organize Safety Data Sheets (SDS), it is essential to implement the following best practices:

-

Establish a Centralized Location: Designate a specific area in your facility for SDS storage, whether in a physical binder or a digital library. This ensures that all personnel can easily access chemical safety data sheets online for essential safety information.

-

Organize by Substance Name or Hazard Class: Arrange SDS alphabetically by substance name or categorize them by hazard class. This systematic approach enhances retrieval efficiency, particularly during emergencies. An effective SDS search procedure is crucial for rapid access to significant details found in chemical safety data sheets online.

-

Regularly Update SDS: Schedule routine reviews at least annually to ensure all SDS are current. Updates should occur whenever new substances are introduced or when regulations change, as maintaining adherence to OSHA standards is vital for workplace safety. Organizations must routinely verify for new data or alterations in substance formulations to keep SDS current and revised.

-

Train Employees: Provide comprehensive training for employees on how to access and interpret SDS. This training should emphasize the importance of these documents in ensuring safety and should be ongoing, especially when new substances or methods are introduced. Employees should feel empowered to take proactive measures regarding their own health and that of their colleagues.

-

Implement a Digital Management System: Utilize an online SDS management system that facilitates easy updates and access. Digital platforms streamline the management process and ensure compliance with OSHA regulations, allowing staff to quickly retrieve chemical safety data sheets online in emergencies. Maintaining open communication with suppliers regarding SDS updates is crucial for ensuring that the SDS reflect the most current information and comply with regulations.

By adopting these practices, your facility can establish a robust system for managing Safety Data Sheets, significantly enhancing safety and regulatory compliance.

Conclusion

Mastering the management of chemical safety data sheets (SDS) is crucial for ensuring workplace safety and regulatory compliance. These documents are essential resources that provide vital information about hazardous substances, guiding safe practices and emergency responses. By effectively utilizing and maintaining SDS, facilities not only comply with OSHA regulations but also foster a safer environment for employees, ultimately reducing the risk of chemical-related incidents.

Key insights from this guide emphasize the importance of understanding the structure and content of SDS, which is standardized into 16 essential sections. Each section plays a pivotal role in hazard communication, from identifying the chemical and its risks to providing first-aid measures and fire-fighting protocols. Furthermore, implementing best practices for accessing, organizing, and maintaining these documents can significantly enhance the safety culture within the workplace. Regular training and updates are also vital to ensure that employees are well-informed and prepared to handle potential hazards effectively.

In summary, prioritizing the management of safety data sheets is not merely a regulatory obligation; it is a fundamental aspect of safeguarding employee health and well-being. By cultivating an environment where chemical safety is taken seriously, organizations can mitigate risks and promote a culture of safety. It is imperative for employers to take proactive steps in mastering SDS management, ensuring that all personnel are equipped with the knowledge and resources necessary to navigate the complexities of chemical safety in the workplace.

Frequently Asked Questions

What are Safety Data Sheets (SDS)?

Safety Data Sheets (SDS) are essential documents that provide comprehensive information about hazardous substances, including their risks, safe handling procedures, and emergency protocols.

Why are Safety Data Sheets important?

SDS are important because they are a regulatory requirement under OSHA standards, ensuring that employers provide access to information about hazardous materials, which directly impacts employee health and safety.

What does OSHA report regarding workplace injuries?

In 2023, OSHA reported around 2.6 million nonfatal workplace injuries and illnesses, highlighting the need for effective communication about hazardous substances.

How has the Hazard Communication Standard changed recently?

The Hazard Communication Standard was revised in 2025 to align with the Globally Harmonized System (GHS), emphasizing the need for accurate and accessible Safety Data Sheets.

What benefits do organizations experience by managing SDS effectively?

Organizations that manage Safety Data Sheets effectively report significant reductions in chemical-related incidents, contributing to a safer work environment and compliance with OSHA standards.

What are the statistics related to workplace injuries and fatalities in 2023?

In 2023, the rate of workplace injuries and fatalities was recorded at 3.5 per 100,000 full-time equivalent workers, indicating ongoing risks that Safety Data Sheets can help mitigate.

What is the role of employers regarding Safety Data Sheets?

Employers must ensure they receive updated SDS and container labels from suppliers and utilize this information to revise their written Hazard Communication plan and training program.

How do Safety Data Sheets contribute to workplace protection?

Safety Data Sheets are integrated into broader workplace protection and compliance strategies, which help safeguard employees and enhance operational efficiency.